NEWS

How to choose materials for circuit boards?

The selection of circuit board boards is crucial for the stability of electronic device performance. Common boards include FR-4, aluminum substrate, flexible substrate, paper substrate, and fiberglass board

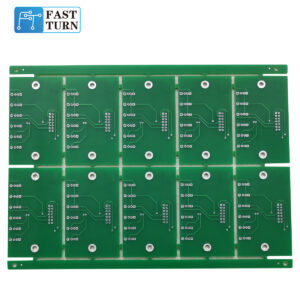

The manufacturing process of PCBA

The production process of PCBA circuit boards includes: PCB design, PCB production, component procurement and inspection, SMT surface mount processing, welding and assembly, testing and debugging, quality inspection and packaging.

Seven commonly used detection methods for SMT

Seven commonly used detection methods for SMT surface mount processing

1、 Visual inspection method for SMT surface mount processing

II Resistance method; 3、 Voltage method; IV Waveform method; 5、 Current method; 6、 Component replacement method; 7、 Step-by-step inspection and separation method

The reasons for component displacement in SMT processing

The reasons for component displacement in SMT processing are complex, including vibration, temperature changes, operational errors, material quality, welding issues, and other factors.

PCB appearance and internal quality inspection methods

The importance and specific methods of PCB appearance and internal quality inspection, including board surface, identification, size, welding quality inspection, as well as board quality, conductivity, insulation performance, thermal performance, and environmental adaptability testing.

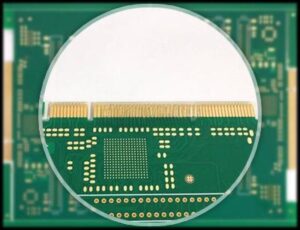

What is a gold finger on a circuit board

As an important component in the electronics industry, the golden finger plays a crucial role in circuit board connections and data transmission.

The role of PCB coordinate files

PCB coordinate files are crucial in PCBA surface mount processing, ensuring precise placement of components, improving production efficiency, ensuring product quality, simplifying production processes, and supporting production traceability and quality control.

Precautions for electronic component installation

In the installation process of electronic components, whether it is manual installation or automated equipment installation, a series of operating norms and precautions must be strictly followed to ensure the quality and reliability of electronic products.

Key points of SMT factory

The key points of comparison between SMT foundries are mainly reflected in equipment and technical capabilities, production management capabilities, quality control capabilities, supply chain integration capabilities, service and support, as well as cost and price.

Which PCB material is suitable for medical equipment

The selection of PCB substrate material for medical equipment is crucial, and it needs to meet requirements such as reliability, stability, electrical and mechanical properties.

SMT working environment requirements

SMT surface mount processing requires a strict working environment, including constant temperature and humidity, dust-free environment, electrostatic protection, good lighting and ventilation, equipment adaptability, and professional training

The role of wave soldering fixtures in PCBA

Wave soldering fixtures play a crucial role in PCBA surface mount processing. It can not only improve welding quality and production efficiency, but also protect circuit boards and components from damage