NEWS

How long is the SMT production cycle?

The SMT production cycle refers to the time required for the entire process from customer order placement to product completion and delivery. This pro

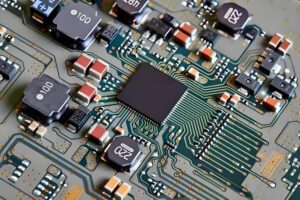

The basic process of PCB surface mount processing

The basic process of PCB surface mount processing includes preliminary preparation, material preparation and inspection, SMT surface mount processing, reflow soldering, and quality inspection and assembly.

How to control the welding quality in SMT surface mount processing?

By optimizing welding parameters, controlling welding environment, improving equipment accuracy and stability, strict material management, strengthening employee training and management, implementing strict quality inspections, and optimizing production processes, we can effectively improve the welding quality of SMT surface mount processing.

SMT Surface Processing Industry Standards and Certification

The SMT surface mount processing industry has strict standards and certification systems, with IPC, ANSI/ESD and other standards ensuring quality, and specific industry quality management systems ensuring compliance with requirements. ISO9001、IPC、CE、 Certification of lead-free processes enhances market competitiveness.

How to optimize the process parameters of SMT surface mount processing?

In SMT surface mount processing, optimizing process parameters is very important, such as welding temperature and time, surface mount pressure and speed, substrate processing and cleaning process parameters need to be finely adjusted

In depth analysis of equipment required for PCBA processing and assembly

In the field of electronic manufacturing, PCBA is a critical process, and achieving high-quality PCBA processing and assembly requires the support of a series of professional equipment.

Welding Quality Standards in PCBA Processing

Welding is a crucial step in PCBA processing, and its quality standards mainly include the following aspects:Welding fullness、Solder Paste Quantity Control、Component misalignment、Floating phenomenon、Tin bead management。

What are the components of PCBA OEM material prices

The price of PCBA outsourcing includes PCB manufacturing costs, material procurement, SMT/DIP plugins, testing, assembly, packaging logistics, and profit margins.

How important is a standardized BOM in PCBA

The BOM table refers to the bill of materials. Before PCBA processing, customers are required to provide the latest BOM table, which includes all electronic components and other materials required for the production of this product

What is the difference between PCBA processing and SMT processing?

The difference between PCBA processing and SMT processing: 1 Different production processes, 2 Different types of components, 3 The production cost varies.

Cost control factors for SMT surface mount

SMT is an important link in the field of electronic manufacturing, and its cost control has a crucial impact on the profitability and market competitiveness of enterprises.

Comparison between SMT Processing and Traditional Plug in Technology

With the continuous development of electronic manufacturing technology, surface mount technology (SMT) processing and traditional plug-in technology have become the two mainstream processes in the field of electronic assembly.